Basic Info

Model NO.: BMPCF

Yarn Type: Combed

Width: 57/58"

MOQ: 1000 M Per Color

Yarn: 20s*16s

Pattern.: Ripstop

Payment: L/C,T/T

Specification: SGS IAF

Specification

| Mareial:100%polyester or TC | Supply Type: In stock Or Make To Order | Port:China | |

| Place of Origin:China(Mainland) | Technics:woven | Export Market:wordwide | |

| Pattern:Jacquard | MOQ:1000m | Payment Terms:L/C,T/T | |

| Specifications | |||

| Product Name | Antistatic Military printing ripstop cotton fabric for Army Garment | ||

| Construction | Yarn count:20S*16S WEIGHT:200gsm width:57/58" | ||

| Color | Any Color | ||

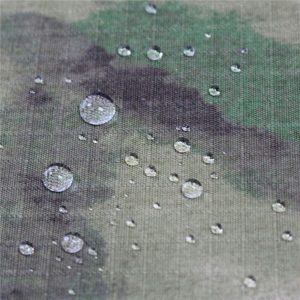

| Feature | waterproof,antistatic,breathable etc | ||

| Usage | Garment,trousers etc | ||

| Finishing | Normal physical treatment after dyeing: | 1) Printing 2) Bronzing 3) Embossed 4) Embroidered 5) Pleated or Crushed(Creased) 6) Cire finish(Oil cire, Heavy cire) 7) Bonded 8) sand/crinkled wash etc | |

| Functional process/treatment: | 1) Waterproof 2) Down proof 3) Coating 4) Teflon 5) Anti-static 6) flame retardant 7) Anti-fungus, 8) Anti-UV | ||

Product advantage

We have all constructions, and we have stock in lots of colors, so deliver time is very short. Production process can according to customers' requirement.

About Our Company

1,Weaving of raw gray fabric

Using the advanced machine to keep the good quality of raw material,worker

are all with experienced persons.

2,Inspect of raw gray fabric

Inspected by experienced workers,keep the perfect raw gray fabric as "A"

grade,keep the defective raw gray fabric as "B" grade,"B" grade fabric is not

allowed to be used without customer's permission.

3,Dyeing of raw gray fabric

Dyed by experienced dyeing factory by experienced worker to keep the color

perfectly,keep the color fastness perfectly,keep the dyeing fabric is eco-friendly,

the handfeel is good and so on.

4,Treatment of dyed fabric

Inspected the dyed fabric by experienced person,reject the defective dyed

fabric and the perfect quality fabric will enter into next process.Handled by

experienced and powerful bonding factory ,coating factory,printing factory

embossed factory and so on.the whole process will be tracked by our 10

years experienced quality person.

5,Packing of finished fabric

Inspected by experienced person in perfect bright room,reject the defective

finished fabric and the perfect quality fabric will be packed as per customer's

instruction.

6,Fabric be loaded and shipped

Handled by experienced person to arrange the shippment for customers.Using

customer's shipping agent or our own shipping agent to ship out the goods.

Advantage

1.Quality and competitive price

We have our own weaving factory and dyeing factory and bonding factory.

All of our factories build up the perfect production system to control the quality.

Our price is very competive as supported by our factories.

2.Experience

We have engaged in the fabric line for 15 years, so we have an experience

sales team who know the market very well and support customers to develop

many projects.

Our experienced quality controlled team and system insure our company

do long term business with customer.

3,Responsible

Responsibility supported our company be bigger.

We take responsibility of the quality of our fabric.

If customer is not satisfy our quality, customer can return back the fabric,we will

take responsible for customers' loss.

4,Business rules

1)Be honest for customer.

2)Hard working for any of custmoers' order,no matter it is big or small quantity.

3)Do higher standards than customers' requirement standard.

4)Keeping quality good and price lower.